Not bothering with a 360 bearing as I want to upgrade the turbo eventually, so just want it working for now

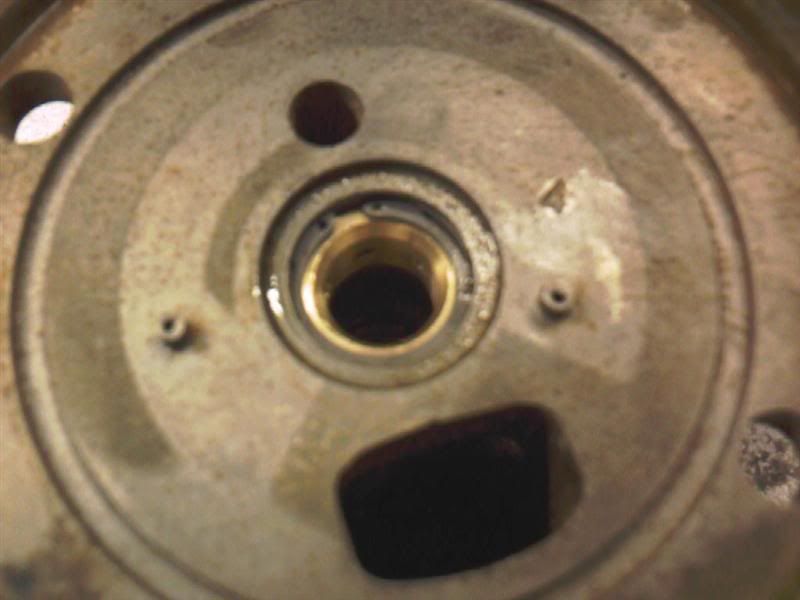

Jack, the bearing can be seen below, it has 90degrees cut out to allow for oil flow I think. So a 360 will be complete...but still allows the oil to flow!

The 270 bearing has three small raised areas, equidistant on the bearing, which act as bearing surfaces....I wonder if the 360 has a bearing ring all the way around, or more bearing surfaces??? nyway, they are reckoned to be a "worth doing" modification.

wrinx

Reply With Quote

Reply With Quote

Bookmarks